Sustainable electrical installation aims to use energy and raw materials efficiently to reduce negative environmental impact. The flat cable method can realize this goal optimally without additional costs and effort.

Energy efficiency

Whenever electricity flows, energy is always lost due to resistance in the cable. This is determined by the material, length and cross-section of the cable. It cannot be avoided, but it can be optimized considerably. Energy-efficient cabling involves the absolute minimum of contact points, the use of high-quality cables and short connection paths.

Resource efficiency

The production of 1 meter of commercially available cable consumes approx. 7.5 kWh of energy and produces approx. 1.3 kg of greenhouse gases per year. These figures illustrate the potential for climate protection in electrical installations. Resource-efficient cabling involves reducing the amount of cable, or rather the amount of copper, to the absolute minimum.

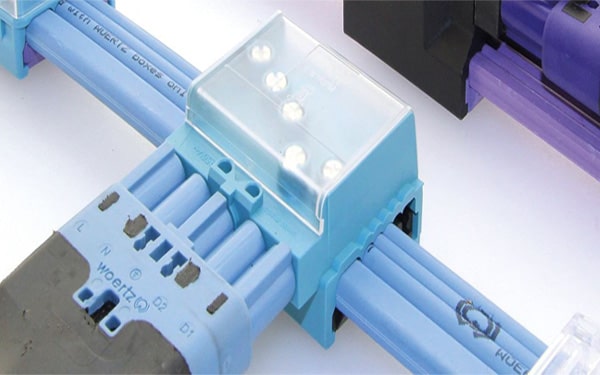

Avoid unnecessary contact points!

There is always contact resistance at contact points. Energy is lost in the form of heat.

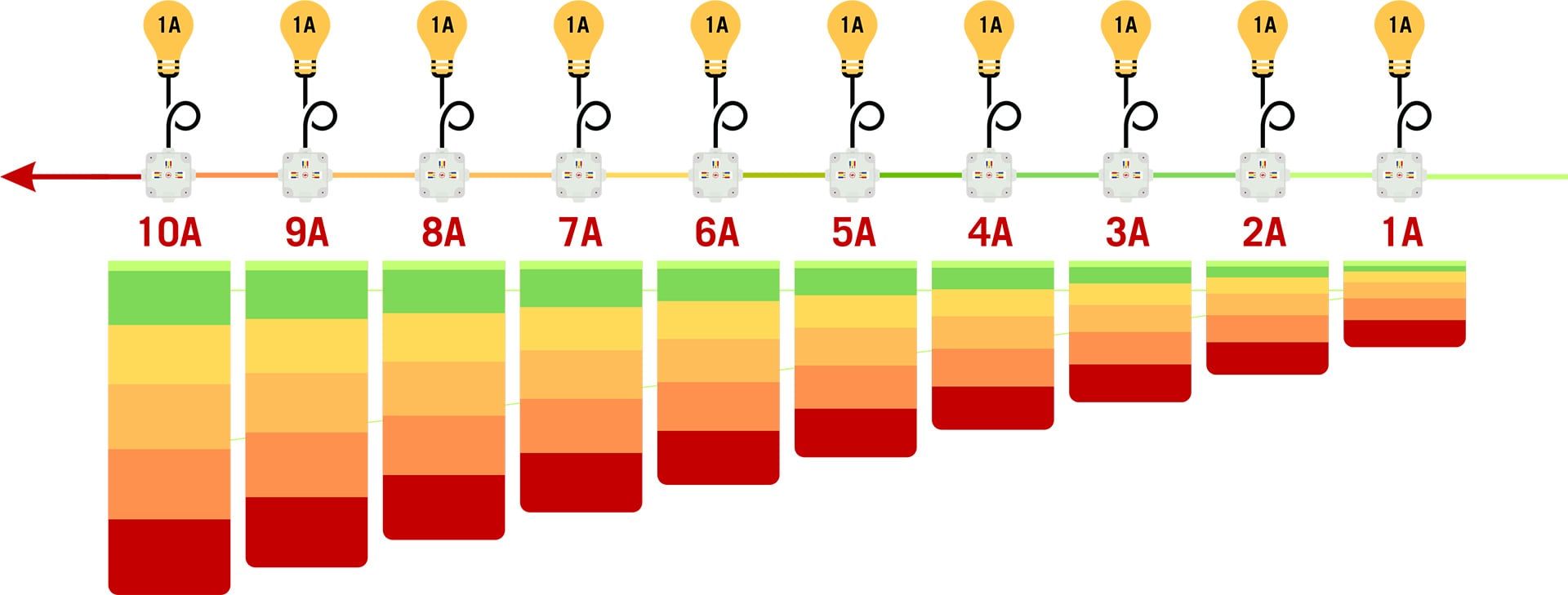

The losses are particularly significant at main lines that supply power. Energy losses add up with every branch.

Depending on the installation method, there may be a different number of contact points on the supply line:

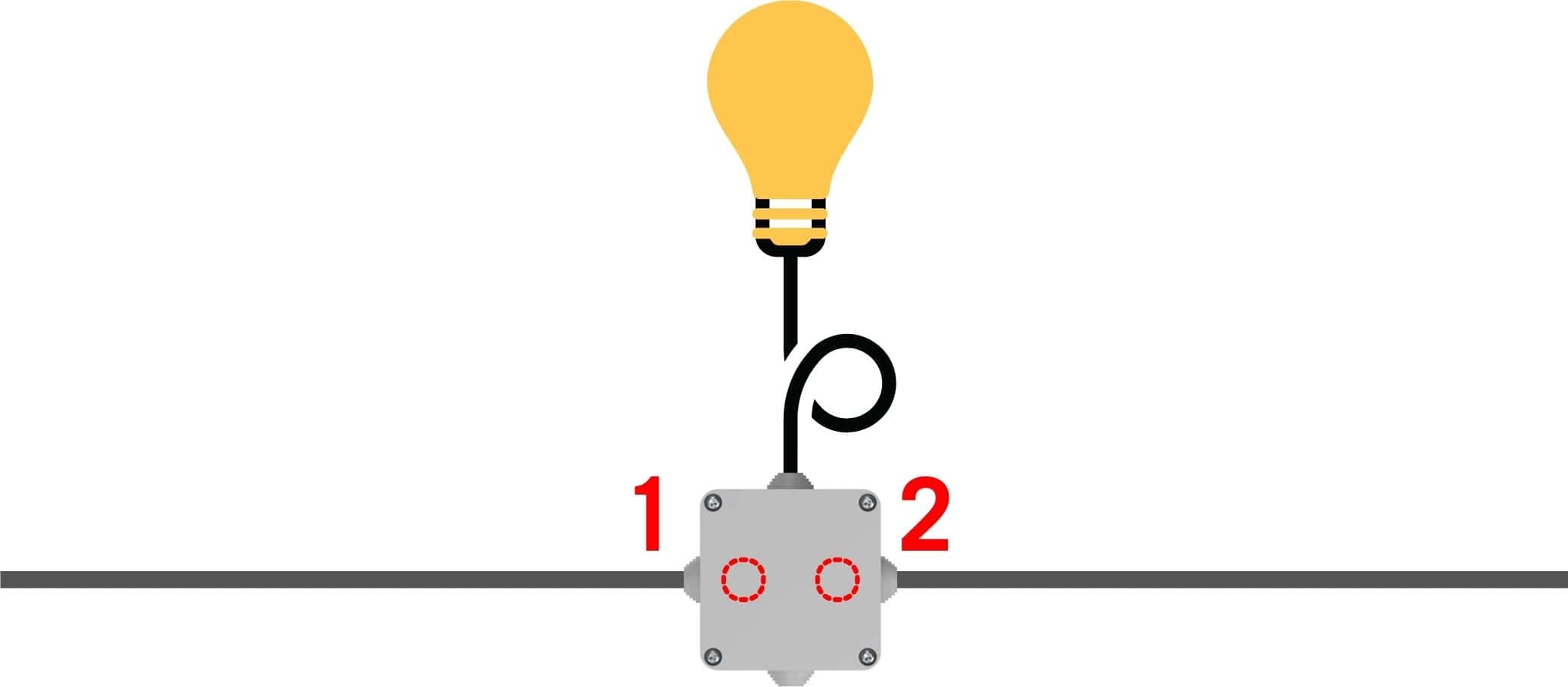

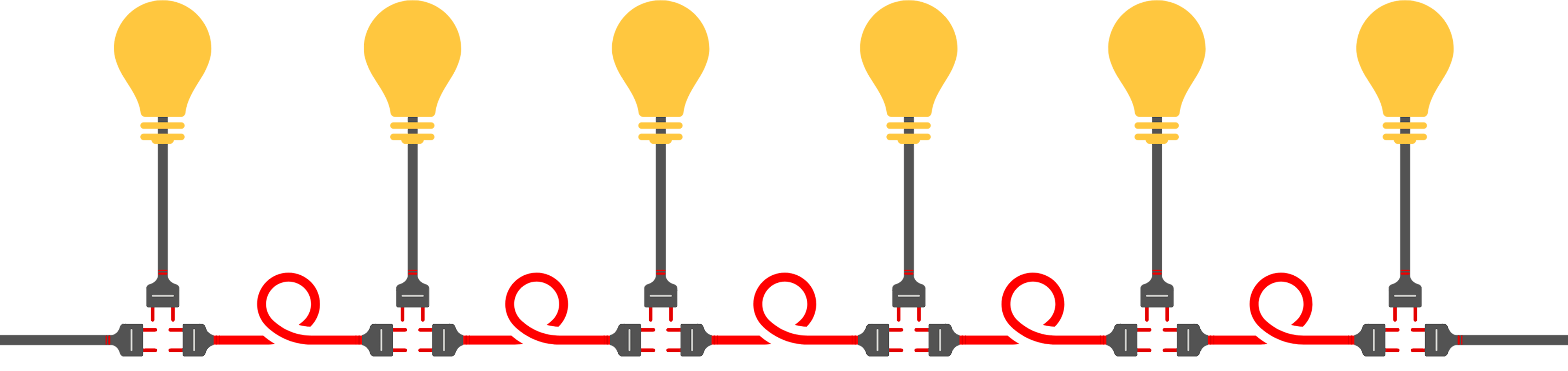

Conventional electrical installation

At least 2 contact points with resistance losses on the supply line per branch.

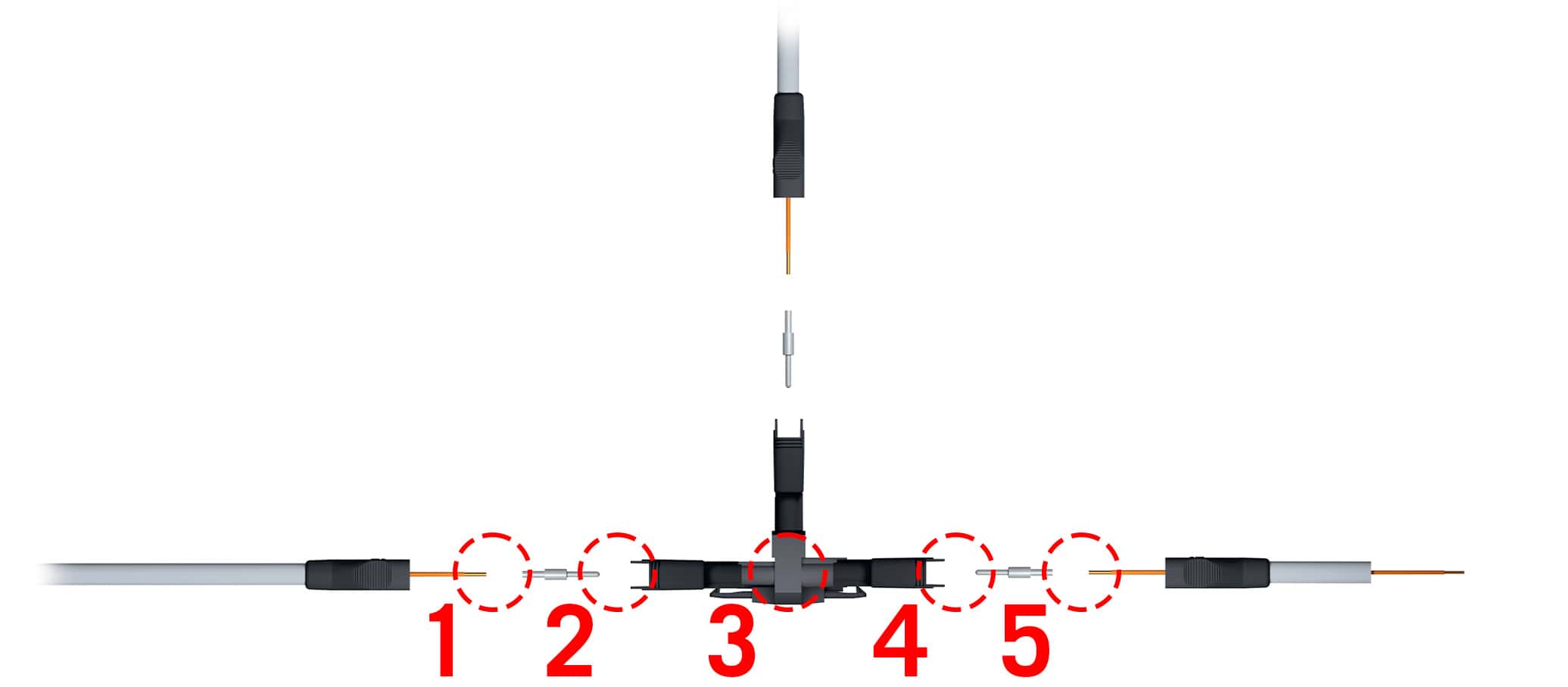

Pluggable electrical installation

At least 4 and often 5 contact points with resistance losses on the supply line per branch.

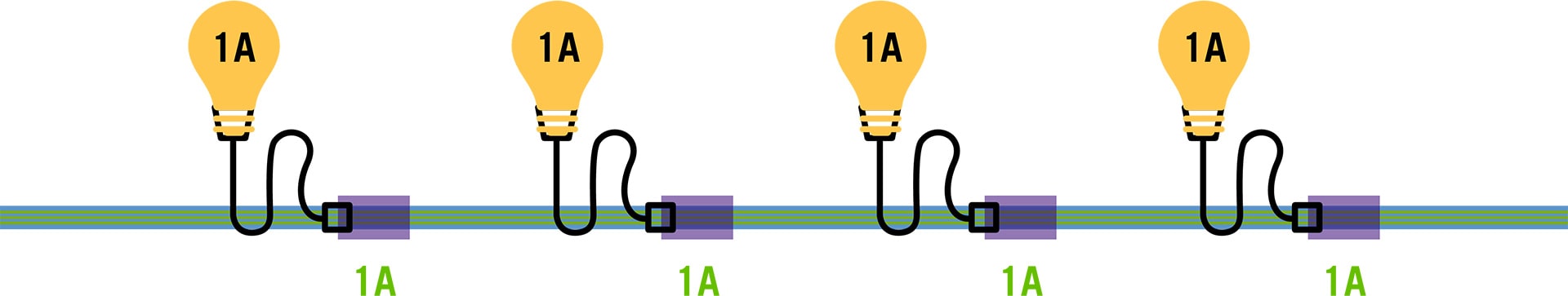

* Branches are attached to the flat cable by means of insulation-piercing contacts without breaking the cable. Voltage losses through the contact point are present only at the discharge point, not on the line supplying the power.

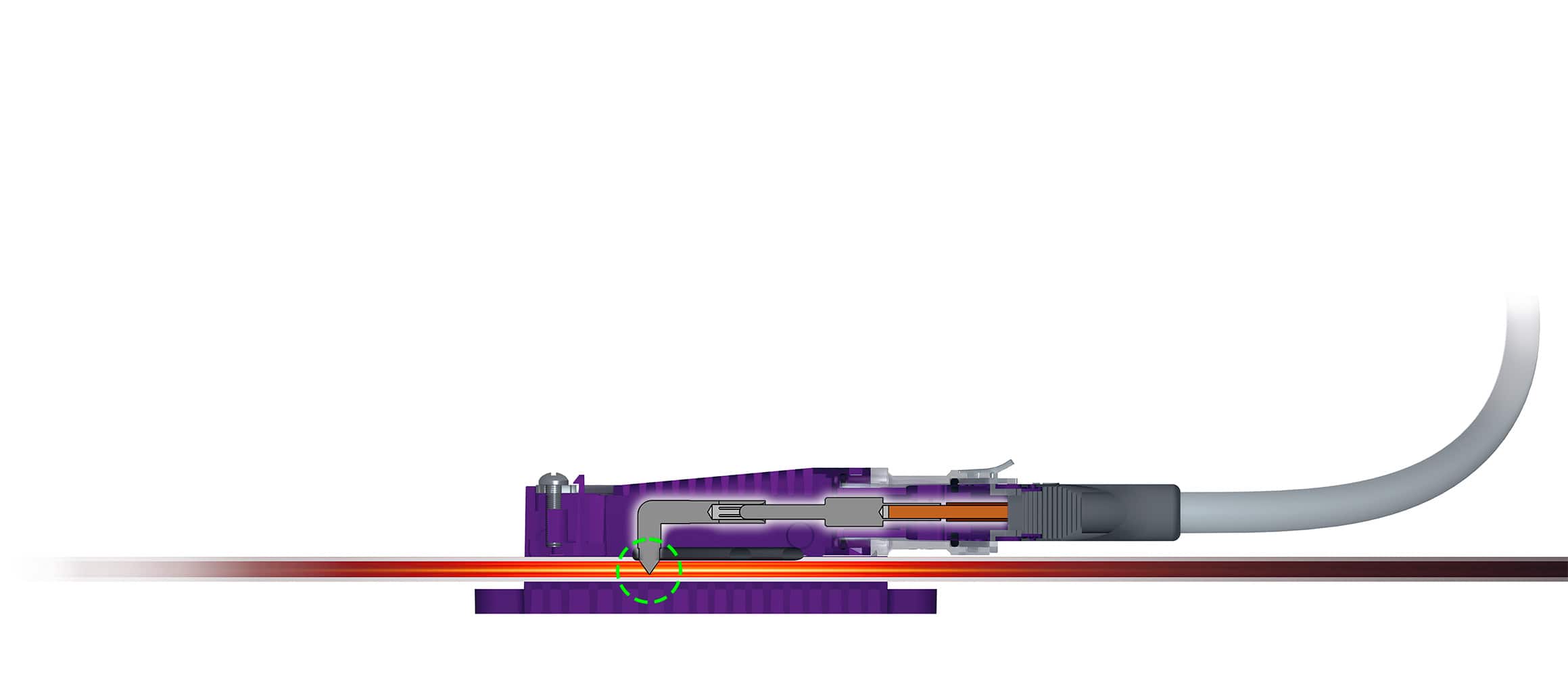

Resistance losses per branch in conventional and pluggable electrical installations

Optimal current flow without additional resistance losses in flat cable installations

Avoid excess lengths.

Electrical installation with flat cables

Since, when using flat cables, the junction box can be attached anywhere on the cable, there are no excess lengths.

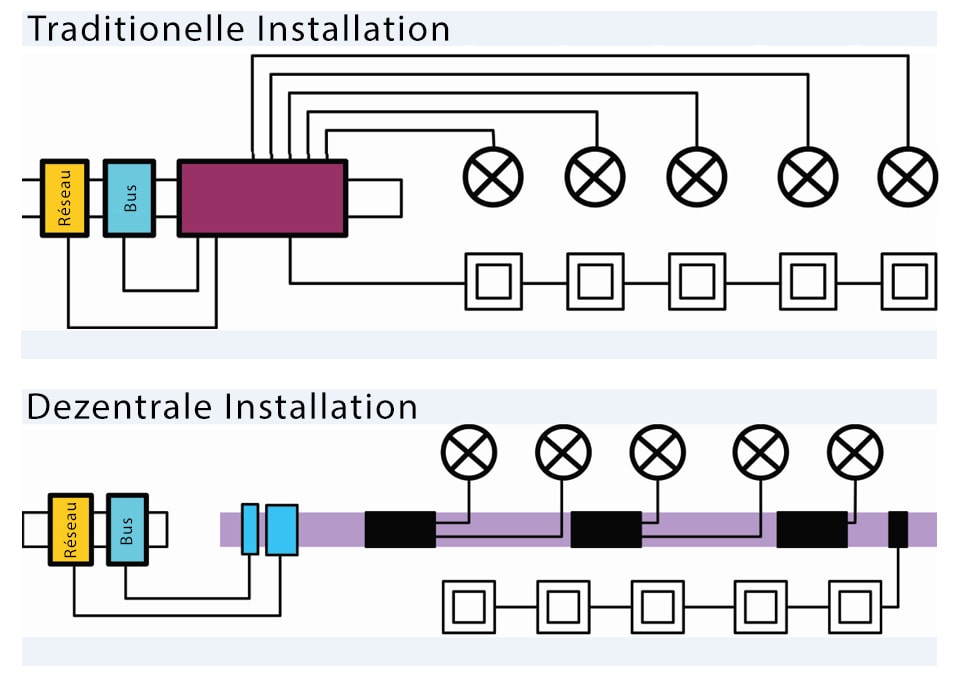

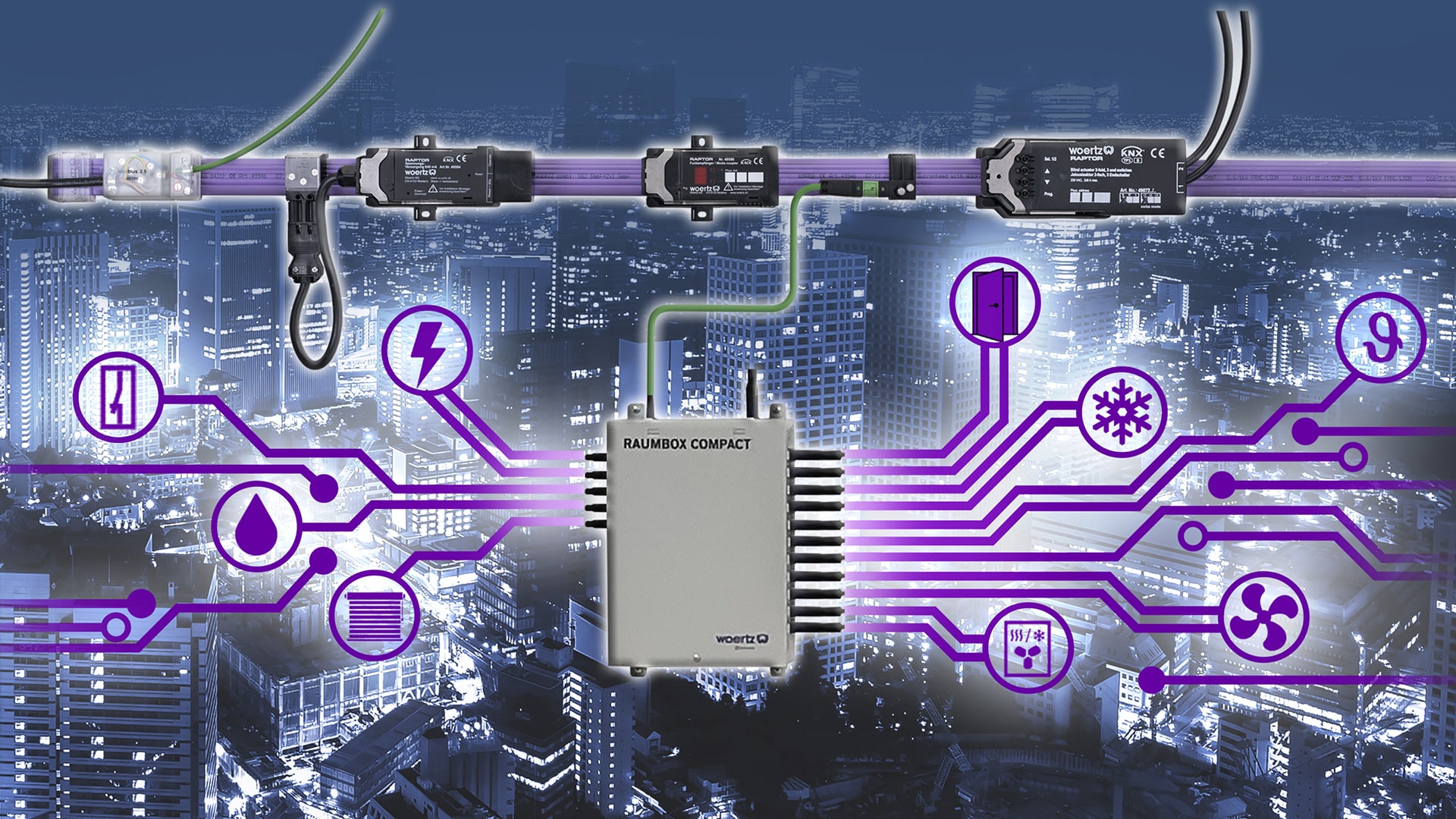

Rely on decentralized intelligence.

With the flat cable system in combination with building automation, up to 80% amount of cable can be saved compared to conventional electrical installation , as elements including fuses can be placed directly on the flat cable and a central control cabinet is no longer required.

Building automation also helps to reduce the ecological footprint of buildings, increase the quality of life of users and achieve cost savings in the long term. This is particularly important as buildings account for a significant share of global energy consumption and CO2 emissions.

Energy is too valuable to be wasted

By choosing an energy-efficient installation method with flat cables, unnecessary energy losses can be avoided. In total, this could save the equivalent of the output of an entire power plant every year in Switzerland.

Every year, around 100 million kilometers of cable are laid in Switzerland. Ten percent of this could be realized with flat cable. Based on an average saving of 40% per cable, around 5200 tons of CO2 would be saved in Switzerland.

This corresponds to the CO2 emissions of a mid-range car circumnavigating the Earth 1000 times or the annual carbon sequestration of half a million trees.

Further information: